© Hong Kong Academy of Medicine. CC BY-NC-ND 4.0

REMINISCENCE: ARTEFACTS FROM THE HONG KONG MUSEUM OF MEDICAL SCIENCES

The pill rolling machine

Edwin CL Yu, FHKAM (Paediatrics), Reg CMP

Croucher Fellow, Honorary Professor, School of Chinese Medicine, Hong Kong Baptist University; Vice-Chairman, Hong Kong Museum of Medical Sciences Society

When studying neurology, a medical student will

come across the term ‘pill-rolling tremor’ as a

diagnostic sign of Parkinson’s disease. It describes

the resting tremor wherein the approximated thumb

and forefinger rub rhythmically against each other

in a rotating movement. In the study of orthopaedic

surgery, he or she may encounter the term ‘pill-roller

hand deformity’ where the pathological contracture

of intrinsic muscles of the hand leads to persistent

extension at the metacarpophalangeal joint and

partial flexion of the inter-phalangeal joints.1 These

descriptive terms hark back to the 19th century

when medicines were dispensed in the form of pills

(from the Latin word pillula meaning ‘little ball’)

manually rolled by professional pill rollers who

were specially trained in the art of preparing and

dispensing drugs.

The Art of Dispensing published in 1915

describes how pills were made.2 A pill comprised a

mixture of active ingredients mixed with a sufficient

amount of some kind of paste or liquid to bind all

into a spherical mass. The active ingredients could

be liquids (eg essential oils), pastes (eg extract of

belladonna), or powders (eg quinine sulphate or

powdered rhubarb). Regardless of the physical state

of the active ingredients, a powder of some kind was

generally required so that the final mixture could be

kept in a desirable solid form, yet sufficiently soft to

be rolled into pills. Before the pill mass was to be

rolled into pills, it was sometimes necessary to add

some inert powder, such as liquorice or sugar of

milk, with an appropriate excipient, to ensure that

the required amount of active ingredient would

be contained in each pill. The massing of pills was

not simple. The professionally trained pill roller

was endowed with the knowledge of the most

appropriate excipient, the right type of mortar and

pestle, and the proper kneading technique. The

amount of active ingredient in the resultant ‘pill

mass’ had to be recorded. For example, a pill mass

might be labelled in Latin-English as ‘Pulv. pro pil.

hydrarg. subchlor. co., 4 grains equal 4 1/2 grains of

pill-mass’. To paraphrase, it meant that four and a

half grains of the pulverised pill mass contained 4

grains of mercuric chloride, the active ingredient.

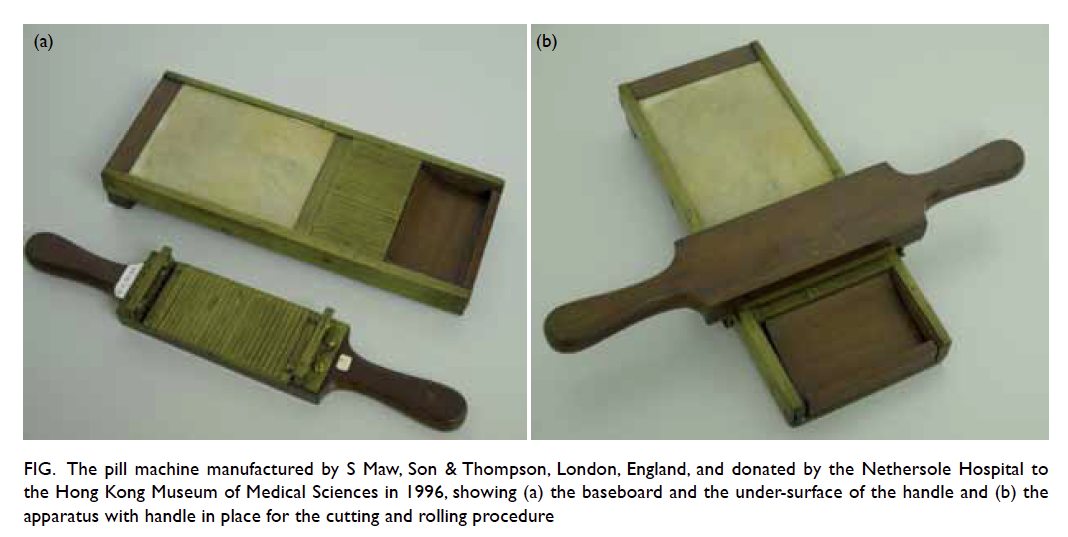

The next stage was to produce the actual pill.

For a long time, this was entirely done by hand.

The pill mass was rolled into the form of a cylinder,

placed on a graduated tile and divided by means

of a spatula into measured lengths calculated to

contain the required amount of active ingredients.

These were then rounded between finger and thumb

to give the final product. Some time in the 19th

century, the hand-operated pill machine such as the

one previously used in the Nethersole Hospital (Fig)

was employed. The cylinder of pill mass was placed

crosswise on the grooved baseboard of the apparatus,

and the two-handled cutter would be placed over it

first to cut it into equal lengths. Rolling the top board

to-and-fro over the cut pieces would then create

spherical pills of equal size and dosage that were

then collected in the sunken tray at the end of the

baseboard. A 12-second videotaped illustration on

the use of the pill roller is available on the internet.3

Figure. The pill machine manufactured by S Maw, Son & Thompson, London, England, and donated by the Nethersole Hospital to the Hong Kong Museum of Medical Sciences in 1996, showing (a) the baseboard and the under-surface of the handle and (b) the apparatus with handle in place for the cutting and rolling procedure

As in this specimen, the machine was, for a

long time, made of wood. Thus over time, shrinkage

of the frame would render the machine useless.

The improved version of the pill machine with the

baseboard fitted between metal sides was invented

by AH Wirz and patented in 1867.4

Pill machines are no longer used in western

medicine, but still common in China for making herb

products. In the West, the apothecary is a historical

name for a medical professional who investigated

herbal and chemical ingredients, and formulated

and dispensed materia medica to physicians and

surgeons for their patients. From the 15th to 16th

century, the apothecary gained the status of a skilled

practitioner, but by the end of the 19th century,

the medical professions in the West had taken on

their current institutional form, with defined roles

for physicians and surgeons, and the role of the

apothecary was more narrowly conceived as that of

a pharmacist (dispensing chemist in Britain).

In China, herbal medicinal products continue to

thrive and herbal mixture must first be crushed, then

ground. Automatic herbal pill–making machines

are used in the bulk manufacture of herbal pills

with the diameter set at 3 mm, 4 mm, 5 mm, 6 mm,

or 7 mm. With fully automatic operation, the herbal

pill–making machine is filled with herbal powder

while honey or water is added. The mixed ingredients

are shaped into pills by the roller, then dried, molded,

and coated.

Today, herb decoction extracts in powder or

granule form have largely replaced the old methods.

Tablets are used. In a more developed technology,

capsules are used to contain the herb ingredients in

extracts. It must, however, be noted that boiling raw

herbs remains a time-honoured tradition.

References

1. Steindler A. The pill-roller hand deformities due to imbalance of the intrinsic muscles, relief by ulnar resection. J Bone Joint Surg Am 1928;10:550-3.

2. MacEwan P. The art of dispensing. Chpt. Pills and their excipients general observations. Part 2. The Chemist and Druggist; 1915.

3. Tomlinson’s chemists Lytham victorian pharmacist demonstrating making pills. Available from (demonstration starts at 0.55): http://www.youtube.com/watch?v=20omeQGKXLI. Accessed Jul 2009.

4. Patent of August H. Wirz of Philadelphia on October 1st 1867. US Patent 69,379. Available from: http://www.google.com/patents/US69379. Accessed Apr 2015.